Replacement Screens for Derrick Hyperpool Plus Shakers/ Derrick Hyperpool PMD+ Shaker

Technical Parameter

• Material: stainless steel 304/316/316 L.

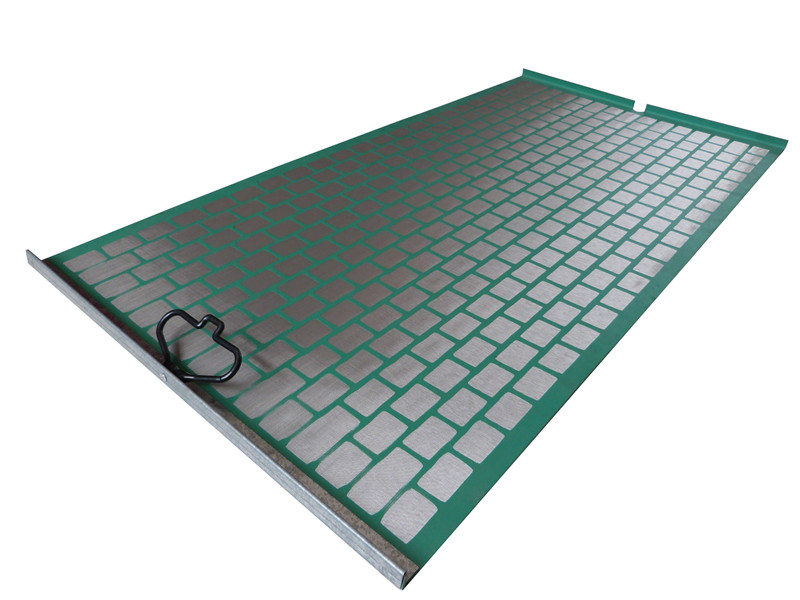

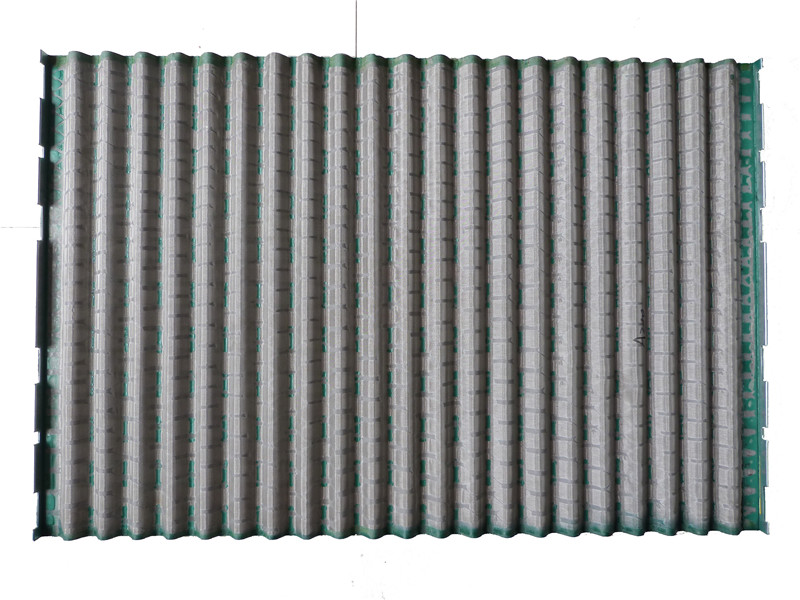

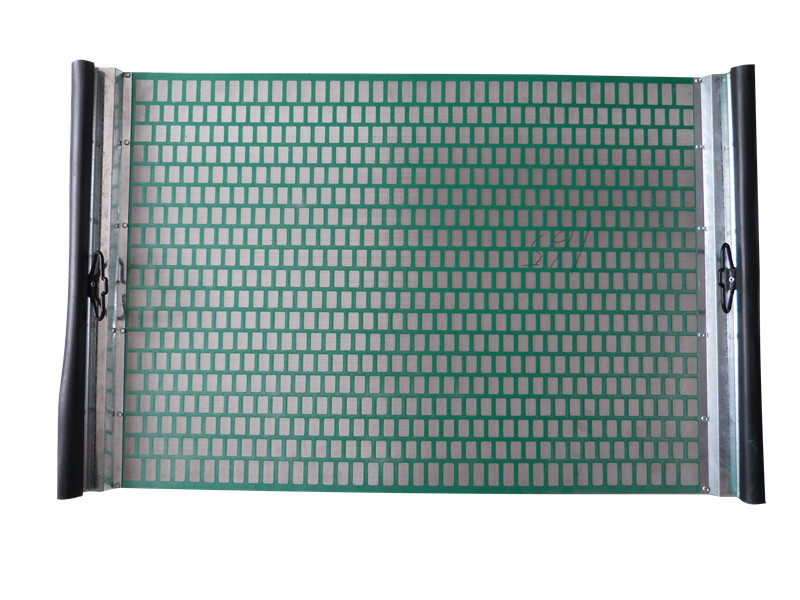

• Construction Type: Wave+ Type.

• Wear Mesh Shape: rectangle.

• API RP 13C Designation: API 20 – API 325.

• Series: DX, DF, HP optional.

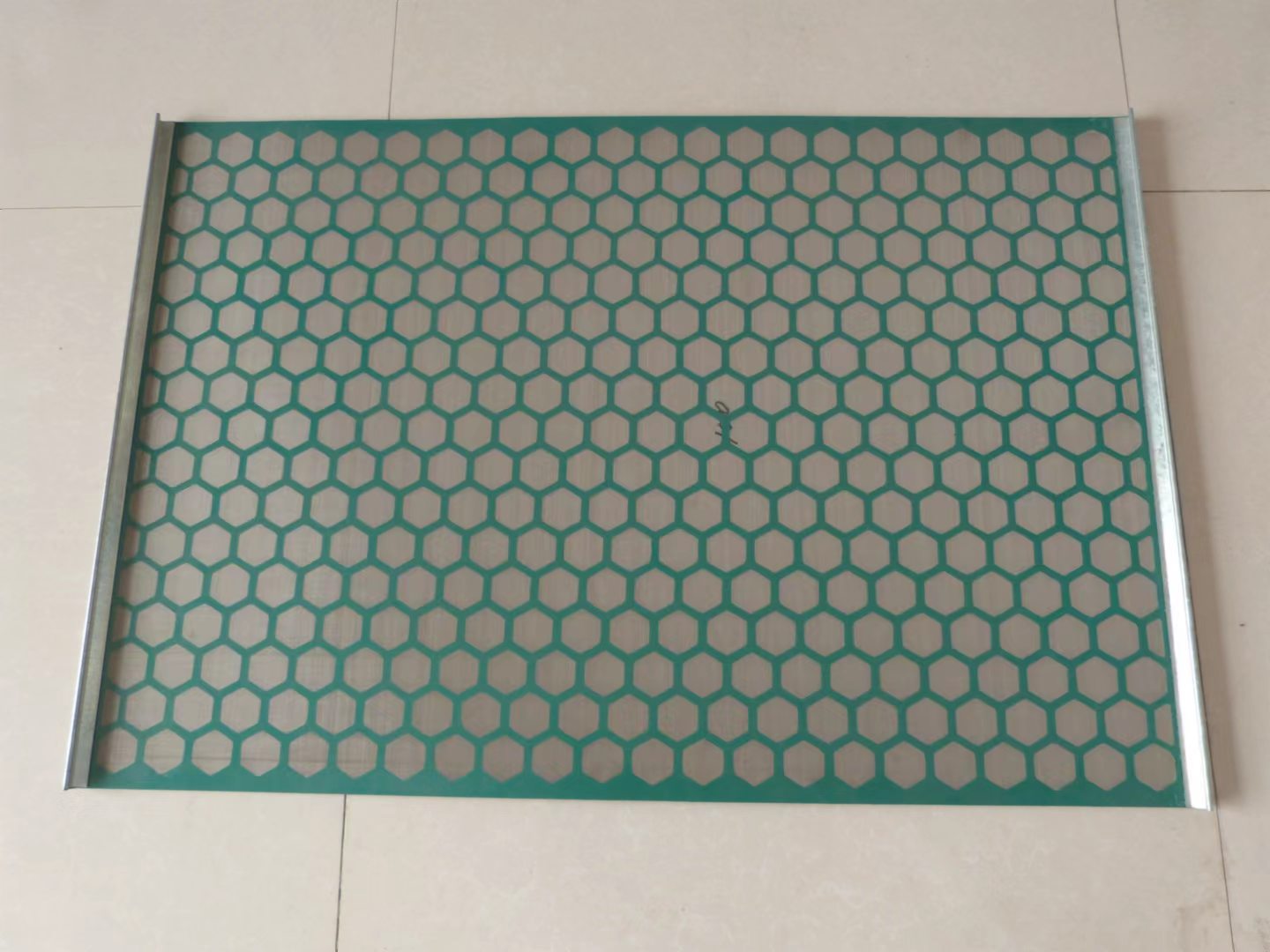

• Color: green.

• Package: 2 pcs per carton, packed in wooden case.

KET-Wave+ DH Shaker Screen is one of the most popular Derrock shaker screens replacement. It is designed for the high capacity Hyperpool 4-panel shale shakers. Installed with pyramid screens, the non-blanked screening area has increased 20% than conventional flat screens. All replacement shaker screens for Derrock shale shakers are all compliant with API RP 13C (ISO 13501), the new industry standard for physical testing and labeling of shaker screens.

Adaptable Shale Shaker Model

KET-Wave+ DH shaker screens are used as the substitute screen for:

• Derrock Hyperpool 4-panel shaker.

• Derrock Triple Hyperpool shaker.

• Derrock Dual Hyperpool with mud cleaner.

• Derrock Hyperpool VE (Vapor Extraction).

Competitive Advantage

• Stainless steel 304/316 wire mesh for longevity.

• Increase shaker capacity and reduce mud loss.

• Non-blanked screening area increased by more than 20%.

• Scientific & reasonable cost control system for competitive price.

• API RP 13C (ISO 13501) compliant.

• Adequate inventory in the shortest time to meet customers' demand.

• Warranty Period: 1 year.

• Working Life: 400-450 hours.

Performance Parameter

|

Screen Designation |

Mesh Type |

API RP 13C Designation |

Conductance Number |

D100 Separation (microns) |

Layer No. |

Non-blank area (sq.ft) |

|

KET-Wave+ DH-A325 |

DF |

API 325 |

0.39 |

44 |

2/3 |

7.69 |

|

KET-Wave+ DH-A270 |

DF |

API 270 |

0.67 |

57 |

2/3 |

7.69 |

|

KET-Wave+ DH-A230 |

DF |

API 230 |

0.71 |

68 |

2/3 |

7.69 |

|

KET-Wave+ DH-A200 |

DX |

API 200 |

1.32 |

73 |

2/3 |

7.69 |

|

KET-Wave+ DH-A170 |

DX |

API 170 |

1.34 |

83 |

2/3 |

7.69 |

|

KET-Wave+ DH-A140 |

DX |

API 140 |

1.89 |

101 |

2/3 |

7.69 |

|

KET-Wave+ DH-A120 |

DX |

API 120 |

1.89 |

134 |

2/3 |

7.69 |

|

KET-Wave+ DH-A100 |

DX |

API 100 |

2.66 |

164 |

2/3 |

7.69 |

|

KET-Wave+ DH-A80 |

DX |

API 80 |

2.76 |

193 |

2/3 |

7.69 |

|

KET-Wave+ DH-A70 |

DX |

API 70 |

3.33 |

203 |

2/3 |

7.69 |

|

KET-Wave+ DH-A60 |

DX |

API 60 |

4.1 |

268 |

2/3 |

7.69 |

|

KET-Wave+ DH-A50 |

DX |

API 50 |

5.17 |

285 |

2/3 |

7.69 |

|

KET-Wave+ DH-A40 |

DX |

API 40 |

8.64 |

439 |

2/3 |

7.69 |

|

KET-Wave+ DH-A35 |

DX |

API 35 |

9.69 |

538 |

2/3 |

7.69 |

|

KET-Wave+ DH-A20 |

DX |

API 20 |

10.88 |

809 |

2/3 |

7.69 |

|

||||||